by ClaytonEng1 | Nov 10, 2023 | Education, News

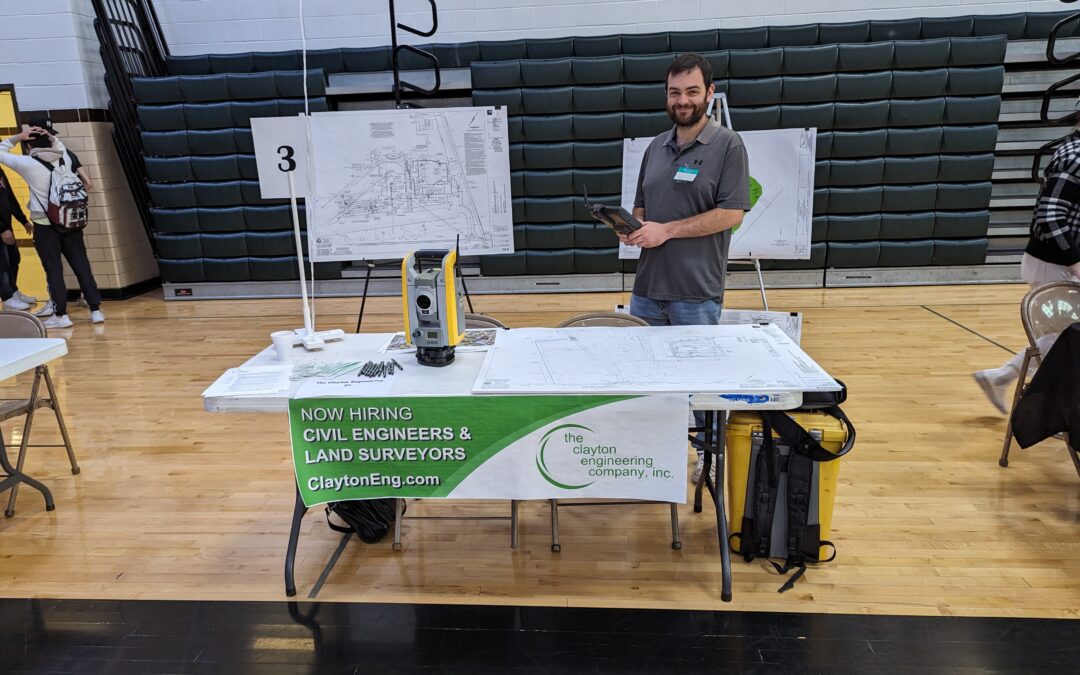

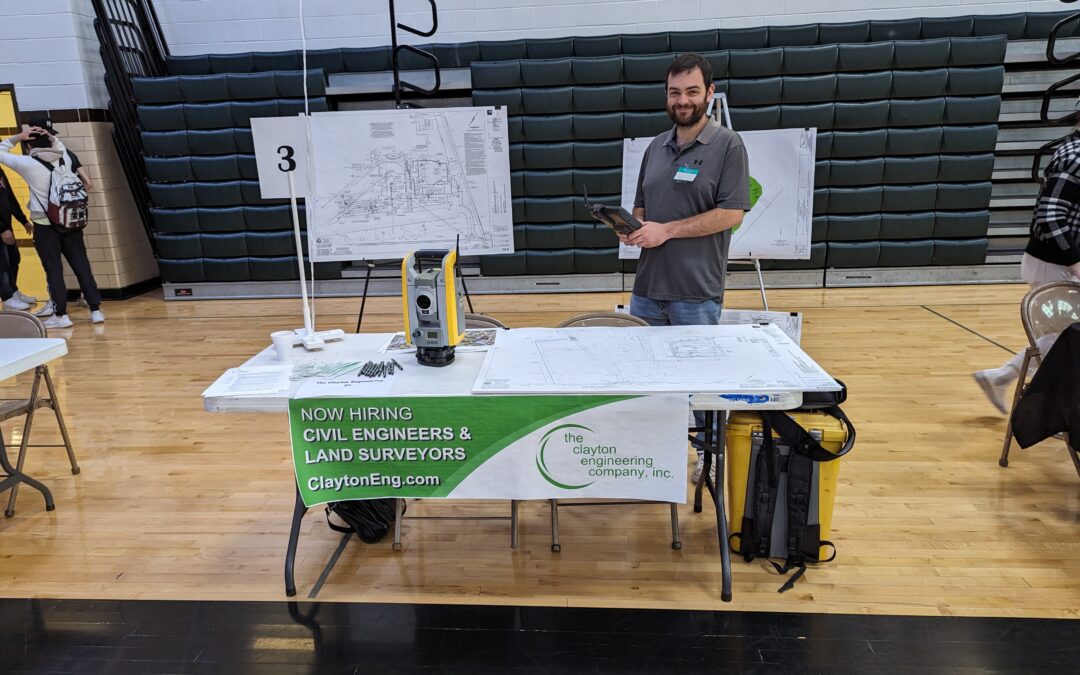

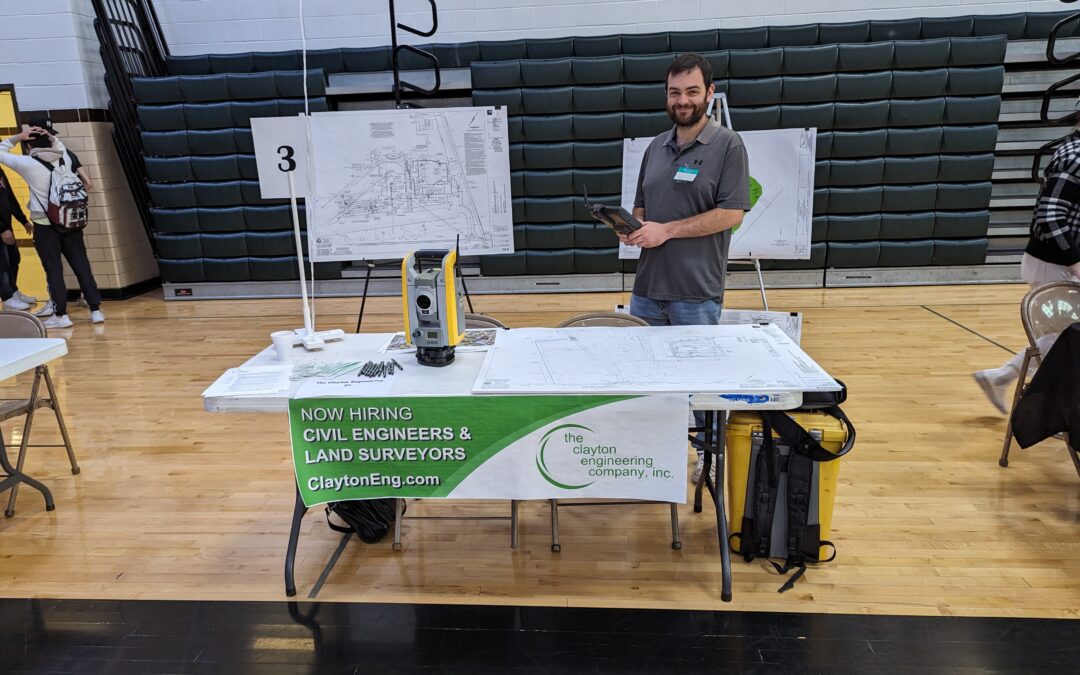

It’s always a great day at the Mehlville Highschool Career fair, where we get to meet the next generation of potential civil engineers and surveyors. We met many eager, young minds who were considering careers in civil design and land survey. We like to wish the best...

by ClaytonEng1 | Oct 17, 2023 | News

The Clayton Engineering Company was proud to sponsor Ranken Jordan’s 5K for play earlier this month. We’re even prouder of our very own Isabel Moreno for placing 22 overall! Way to go...

by ClaytonEng1 | Aug 21, 2023 | Education, News

The Webster Groves School District will build a new athletic complex to replace the aging Moss Field facility on S. Elm Avenue. This project was funded through the recently approved bond issue by voters in the district. We are proud to be a part of the design team for...

by ClaytonEng1 | Aug 12, 2023 | News

Professional Land Surveyor - Project Manager Responsibilities include: Work on various projects primarily in the St. Louis Metro Area and adjoining Illinois areas, as well as preparing proposals, boundary surveys, ALTA Surveys, construction staking calculations and...

by ClaytonEng1 | Jul 3, 2022 | News

St. Louis Bread Company (Panera Bread) at Four Seasons Plaza, in Chestefield moved to a different location in the plaza, adding a drive through lane. Clayton Engineering worked on the civil engineering and site layout for this project.

by ClaytonEng1 | Jul 3, 2022 | News

U-Gas Various Locations – Clayton Engineering works regularly with U-Gas for various types of Land Surveying, Topographic Surveying, Civil Engineering, Planning & throughout the Development Stages of multiple projects. Clayton Engineering provides the Construction...